Customization

CUSTOMIZED PROCESS

The customization process for all of our equipment usually involves multiple steps to ensure that the final product meets the specific needs and standards of the customer. The following is the basic process of general sterilization equipment customization:

Demand Analysis

Design Stage

Material Selection

Manufacturing And Assembly

Test And Commissioning

Customer Acceptance

After-Sales Service

Demand Analysis

Firstly, communicate with customers to understand their specific needs, including the type of products to be treated, the expected effect, the use environment of the equipment, the scale of production, etc. This helps determine the specifications and functions of the device.

Design Stage

Design the equipment according to the results of demand analysis. This includes choosing the right technology, designing the structure of the equipment, determining the way to heat and hold the equipment, and considering the ease of operation and safety of the equipment.

Material Selection

Select materials suitable for product contact and ensure that these materials meet safety standards. At the same time, consider the durability and cost effectiveness of the material.

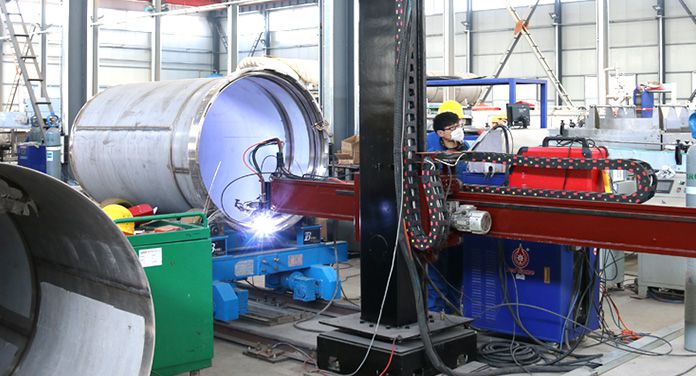

Manufacturing And Assembly

Manufacture and assembly of the equipment according to the design drawing. This includes welding, installing heating elements, connecting pipes, etc., to ensure that all components are properly installed and the equipment can operate properly.

Test And Commissioning

After the equipment is assembled, test and commissioning are carried out to ensure that the equipment can achieve the expected effect. This may include pressure testing of the equipment, temperature testing, etc., to ensure that it performs as designed.

Customer Acceptance

The equipment will be delivered to the customer for acceptance. The Customer shall check whether the appearance and performance of the equipment meet the requirements of the contract and make any necessary adjustment or improvement suggestions.

After-Sales Service

Provide necessary training and support to ensure that customers can properly operate and maintain the equipment. Provide warranty service to solve any problems that may arise.

CUSTOMIZATION CAPABILITY

The customization capability includes three levels: shallow customization, medium customization and deep customization.

Light customization mainly focuses on the appearance of the equipment customization (such as spray paint color).

Medium customization In addition to the appearance customization of the equipment, it also includes the redesign and customization of the product shape and combination.

Deep customization In addition to the redesign and customization of the shape and combination, there are changes and customization of the internal structure, function additions and subdivisions.

These grades are divided to meet the needs of different customers and market positioning .

CUSTOMIZATION RANGE

01

Sterilization equipment customization range

The minimum diameter can accept 300mm. Straight cylinder length is not limited, according to customer needs can be customized.

02

Sandwich pot customization range

From 100L to 1000L can be customized.

03

Steam generator customization range

From 100kg/h to 1000kg/h.

04

Assembly line customization range

According to the output from small to large can be customized.

CUSTOMIZED PRODUCT

QUICK LINKS

QUICK LINKS

CONTACT US

Tel.&Wechat:

+86 183 6635 0187

E-mail:

WhatsApp:

Add.:

Mizhou industry park Guanhai road. No. 2800 Zhucheng city, Shandong province, China

GET IN TOUCH

GET IN TOUCH